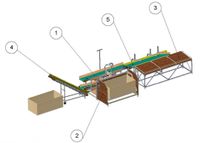

Manual cleaning lines

Furthermore, NOSMA offers you the well-tried manual fettling lines.

- Cleaning belt - cleaned cabbage is put down and transported to size-weight sorting.

- Box tilting device - cabbage is manually removed from the large box, stalk cut and then cleaned under the air nozzle.

- Packing table - cabbage is packed e.g. into bags or market boxes.

- Waste belt - which runs below the cleaning station e.g. into a large crate.

- Sorting or weighing belt - cabbage is sorted by weight (a scale is built into the conveyor belt which gives an impulse to the corresponding paddle for ejection) or by volume (via height-adjustable sorting rollers).

A cleaning station consists of two cleaning places, each equipped with a cleaning nozzle and waste hopper. We use one blower for each cleaning station.

Such cleaning lines can be extended as required and can of course also be arranged differently, in short they can be planned individually for each operation. These cleaning lines are available in galvanized or stainless steel.

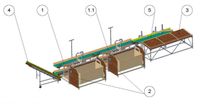

- Cleaning belt - cleaned cabbage is put down and transported to size-weight sorting.

- Box tilting device - cabbage is manually removed from the large box, stalk cut and then cleaned under the air nozzle.

- Packing table - cabbage is packed e.g. into bags or market boxes.

- Waste belt - which runs below the cleaning station e.g. into a large crate.

- Sorting or weighing belt - cabbage is sorted by weight (a scale is built into the conveyor belt which gives an impulse to the corresponding paddle for ejection) or by volume (via height-adjustable sorting rollers).

- Cabbage feeding belt - A large crate of cabbage is dosed onto the feeding belt via the crate tipping device. Belts and crate tipping device are controlled by a light barrier. In this way, each cleaning station has enough cabbage "in stock" for cleaning.

Cleaning station also available separately, with two cleaning stations or cleaning nozzles.

1. underneath the cleaning nozzles are rollers on which the cabbage can be placed,

rolled and cleaned.

2. below this is the waste funnel for leaves and stalk cuttings which leads to the waste conveyor.

Cleaning station galvanized or stainless steel; built-in blower soundproofed.

After cleaning, there are various options for sorting and packaging depending

on customer requirements.

The output depends on the number of cleaning stations and, of course, the weight of the cabbage. One cleaning station cleans approximately 1 ton of cabbage (2 - 2.5 kg) per hour.

The underside of the cabbage is cut off and the outer leaves are blown off with an air jet.